STELLANTIS - FREIGABE FÜR EMISSIONSPRÜFUNGEN (VIAQ)

TISAX® - imat erreicht wichtigen Meilenstein

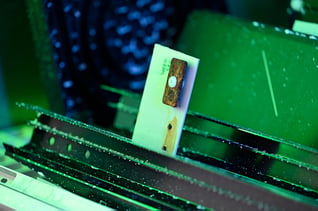

Elektrische Bauteilprüfung

Emissionen & Geruch

Textilprüfungen

Lebensdauer

Korrosion

Umweltsimulation

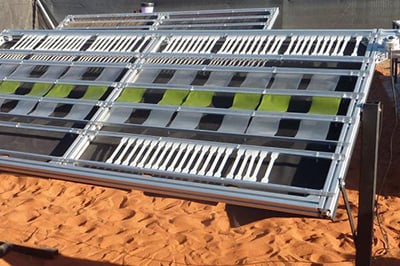

Freibewitterung

WIR SIND DER STRATEGISCHE PARTNER DER AUTOMOBILINDUSTRIE

Als global akkreditierter Prüfdienstleister spezialisieren wir uns auf die Validierung und Beratung in der Automobilindustrie. Wir sind Ihr zuverlässiger Partner im gesamten Bemusterungsprozess, von der sorgfältigen Bewertung von Materialien und Bauteilen bis hin zur umfassenden Analyse von Gesamtfahrzeugen. Ob im Innenraum oder im Exterieur, unsere Expertise garantiert Qualität und Innovation in jedem Detail.

Unser Team aus erfahrenen Fachleuten bietet maßgeschneiderte Lösungen, die auf die spezifischen Anforderungen von Automobilzulieferern und -herstellern zugeschnitten sind. Wir verstehen die Komplexität und Herausforderungen des heutigen Marktes und setzen uns dafür ein, Ihre Produkte nicht nur an die aktuellen Standards anzupassen, sondern diese zu übertreffen und zukunftssicher zu gestalten.

First choice in automotive validation & consulting

SIE SUCHEN EINE PRÜFNORM? LIEFERVORSCHRIFT? METHODE?

Leider wurden keine Treffer zu Ihrer Suche gefunden. Versuchen Sie, Ihren Filter zu ändern und die Suche zu wiederholen.

ERPROBUNG UND VALIDIERUNG

Sicher. Vom Granulat bis zum Gesamtfahrzeug: Wir haben die Komplettlösung für Emissions- und Geruchsprüfungen.

MEHR ERFAHRENStrapazierfähig. Umfassende Textilprüfungen aller gängiger Automobil-Prüfnormen. Weiterentwicklung von Standards und Equipment.

MEHR ERFAHRENLanglebig. Normgerechte Lebensdauer- und Belastungsprüfungen für Bauteile und Fahrzeuge.

MEHR ERFAHRENWiderstandsfähig. Wir testen die Qualität von Werkstoffen und Beschichtungen nach internationalen Prüfverfahren.

MEHR ERFAHRENExtrem beständig. Mit einem breiten Spektrum an Klimaprüfungen und Alterungen gehen wir Schwachstellen an Material und Bauteilen auf den Grund.

MEHR ERFAHRENWetterfest. In mitteleuropäischem Klima oder extremen Umwelteinflüssen auf den Testfeldern in Südafrika: Wir stellen Fahrzeuge, Bauteile und Materialien vor große Herausforderungen.

MEHR ERFAHRENERPROBUNG UND VALIDIERUNG

Sicher. Vom Granulat bis zum Gesamtfahrzeug: Wir haben die Komplettlösung für Emissions- und Geruchsprüfungen.

MEHR ERFAHRENElektrisch. Mit vollem Einsatz und Spannung durchlaufen Ihre elektrischen Komponenten diverse Stationen.

MEHR ERFAHRENExtrem beständig. Mit einem breiten Spektrum an Klimaprüfungen und Alterungen gehen wir Schwachstellen an Material und Bauteilen auf den Grund.

MEHR ERFAHRENWetterfest. In mitteleuropäischem Klima oder extremen Umwelteinflüssen auf den Testfeldern in Südafrika: Wir stellen Fahrzeuge, Bauteile und Materialien vor große Herausforderungen.

MEHR ERFAHRENWiderstandsfähig. Wir testen die Qualität von Werkstoffen und Beschichtungen nach internationalen Prüfverfahren.

MEHR ERFAHRENLanglebig. Normgerechte Lebensdauer- und Belastungsprüfungen für Bauteile und Fahrzeuge.

MEHR ERFAHRENStrapazierfähig. Umfassende Textilprüfungen aller gängiger Automobil-Prüfnormen. Weiterentwicklung von Standards und Equipment.

MEHR ERFAHRENBeständig. Vertrauen Sie auf unsere langjährige Erfahrung, um sicherzustellen, dass Ihre Materialien und Bauteile den anspruchsvollen Automobil-Standards für den Fahrzeuginnenraum entsprechen.

MEHR ERFAHRENTRUSTED BY AUTOMOTIVE LEADERS

TRUSTED BY AUTOMOTIVE LEADERS

Das sagen unsere Kunden

"I like your coordination team because of your dynamism and trustworthiness."

"offers are well prepared and clearly structured"

“Thank you very much for your response and for your focus on understanding and satisfying customer needs”

"Excellent support in case of questions and clarifications"

"Thank you very much for your constant support and prompt reply."

“You have always been a great help. It has been an absolute delight to work with you”

"I am currently very happy with the services provided and the processing time"

GLOBALER STANDARD

Sie erwartet weltweit ein hohes Maß an Qualität.

Wir arbeiten gemäß DIN EN ISO 17025, ISO 9001, TISAX® und VDA 6.2. oder verschiedenen internationalen OEM-Anforderungen.

FULL SERVICE

Wir sind in der Lage alle Anforderungen an ein Material oder Bauteil vollständig zu prüfen.

Profitieren SIe von der unkomplizierten, bequemen Abwicklung Ihrer Aufträge.

EXPERTISE

Hoch qualifizierte und motivierte MitarbeiterInnen unterstützen Sie bei Ihren täglichen Herausforderungen. Lassen Sie sich von über 30 Jahren Automobil-Erfahrung überzeugen.

AKKREDITIERUNGEN, ZERTIFIKATE &

OEM FREIGABEN

DIN EN ISO/ IEC 17025, ISO 9001, VDA 6.2,

diverse OEM Freigaben u.v.m.

DOWNLOADS

NEWSROOM

In unserer Newsübersicht finden Sie alle Neuigkeiten über unser Unternehmen auf einen Blick.

ZUR ÜBERSICHTIn unserem Newsroom erhalten Sie Hintergrundinformationen und Bildmaterial.

ZUR ÜBERSICHTWerfen Sie einen Blick rein, welche nächsten Veranstaltungen, Online-Events wir anbieten.

ZUR ÜBERSICHTNewsroom

Wir informieren Sie zu wichtigen Themen aus den Bereichen Erprobung und Validierung von Bauteilen in der Automobilindustrie. Mehr als 7000 Experten – aus der Automobil-, Kunststoff- und Textilindustrie haben sich bereits angemeldet.

Druckwasserstrahl-Prüfung in der Automobilindustrie

Mehr lesenEin erfolgreicher Auftritt auf der Material District Messe in Utrecht!

Mehr lesenFormaldehyd in Fahrzeugen: Herausforderungen für die Automobilindustrie

Mehr lesenStellantis: Freigabe für Emissionsprüfungen erfolgreich (VIAQ)

Mehr lesenTISAX® - imat erreicht wichtigen Meilenstein

Mehr lesenVDA 276: Gibt's die eigentlich noch?

Mehr lesen

WERDE TEIL UNSERES TEAMS!

Du bist bereit, dich ständig weiterzuentwickeln? Du hast einen hohen Qualitätsanspruch und die Fähigkeit selbstständig zu arbeiten? Du suchst eine Herausforderung in einem jungen und zukunftsorientierten Unternehmen?

Wir freuen uns Dich kennenzulernen.