Emissions & odor in the vehicle interior (VIAQ)

EMISSION AND ODOR TESTS

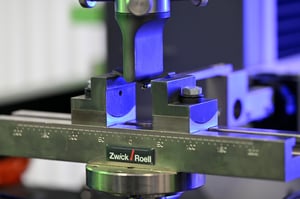

Are you faced with the challenge of complying with the emission limits of your interior components while keeping an eye on costs and time? With our extensive experience and state-of-the-art testing procedures, you can be sure that your materials and components are validated according to the latest standards.

In modern vehicles, the air quality in the interior is a decisive factor for the well-being of the occupants. In addition to comfort, manufacturers and suppliers focus above all on the health and safety aspects of the materials. Chemical substances released from plastics, textiles and paints can cause unpleasant odors and potential health risks. In addition, "fogging", i.e. the condensation of substances on cold surfaces, can impair visibility through the windscreen and endanger road safety. We use precise test methods to systematically record emissions, odor behavior and fogging properties. In this way, we support the automotive industry in meeting strict standards while ensuring a pleasant and safe interior atmosphere.

Our accreditations and approvals

imat has long held various accreditations, certifications and OEM approvals, which ensure that orders are processed in accordance with standards and processes.

Are you looking for an exam? Standard? Specifications?

Accredited & certified tests

EXTENSIVE EMISSION ANALYSES

Are you faced with the challenge of complying with the emission limits of your interior components while keeping an eye on costs and time? With our extensive experience and state-of-the-art testing procedures, you can be sure that your materials and components are validated to the latest standards. We know how important it is for you to get accurate and meaningful results that help you achieve your quality goals while meeting your project deadlines .

SECTION TEAM - TITLE

Description. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et

- Tab Title

BLOG

Formaldehyd in Fahrzeugen: Herausforderungen für die Automobilindustrie

Read moreStellantis: Freigabe für Emissionsprüfungen erfolgreich (VIAQ)

Read moreVDA 277 vs. VDA 278: Was ist der Unterschied?

Read moreGeruchsunterschiede bei Polypropylen: Die Rolle von Faserverstärkung und Verarbeitungsparametern

Read moreWarum sind die Einheiten der Ergebnisse von Prüfungen der Werkstoffemissionen eigentlich so unterschiedlich?

Read moreGrenzwerte für Formaldehyd und Formaldehydabspaltern in Fahrzeugen

Read moreOUR SERVICE PORTFOLIO

Rely on over 30 years of automotive testing expertise

componentsLearn more

TRUSTED BY AUTOMOTIVE LEADING INDUSTRY

Automobile manufacturers worldwide such as Mercedes-Benz, BMW, Porsche, Tesla & Co. as well as suppliers trust in our expertise and reliability.